MAINTENANCE AND EXPERTISE SERVICES

CONTROL AND ANALYSIS OF MECHANICAL PARTS

- Dimensional control

- Roughness measurements

- Wave control

- Hardness, micro-hardness

- Metallographic analysis

- Dip penetrant testing (COFREND qualification)

- Roll profile recording

- Coating expert appraisals

- On site inspection

CERTIFICATIONS & QUALIFICATIONS

- ISO 9001

- EN 9100

- NADCAP in progress

- ISO 14000

Numerous qualifications in aeronautics, aerospace and energy.

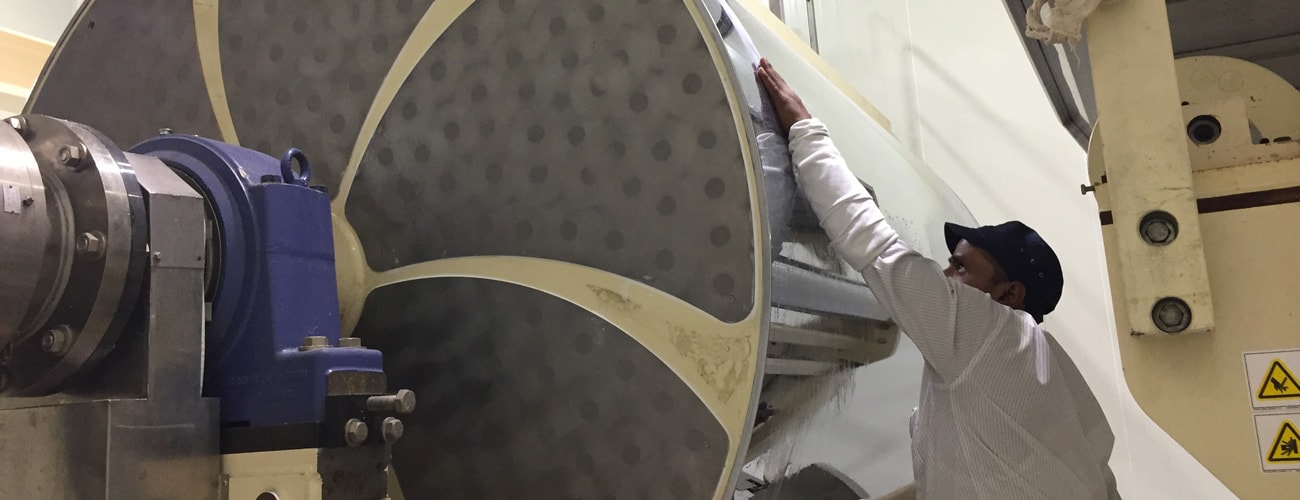

MAINTENANCE SERVICES AND EXPERTISE FOR ROLLS

Thermal control:

Control of heat exchange effectiveness of a circulating roller through a high definition thermal infra-red camera (high frequency dynamic record and data processing software package).

We are able to perform two types of control:

In production condition: to draw up a heat balance of the installation according to the production conditions and highlight the possible thermal exchange problems.

In thermal shock condition: at Polimiroir plant or directly on production line, this test makes it possible to reveal the internal circulation of the roll, to identify the technology, to control the quality of circulation and to determine the cooling speed of the roll analyzed.

Chemical cleaning by internal circulation:

Operations of descaling, or chemical cleaning to ensure the circulation of fluids inside rolls.

RESEARCH & DEVELOPMENT

The group has, for several years, invested heavily in its research resources.

The investments made in our laboratories and in new processes, allow our Doctors and Engineers to launch more and more complex research files.

Our strong policy in these areas has allowed us to enter into European development projects.